Engineering

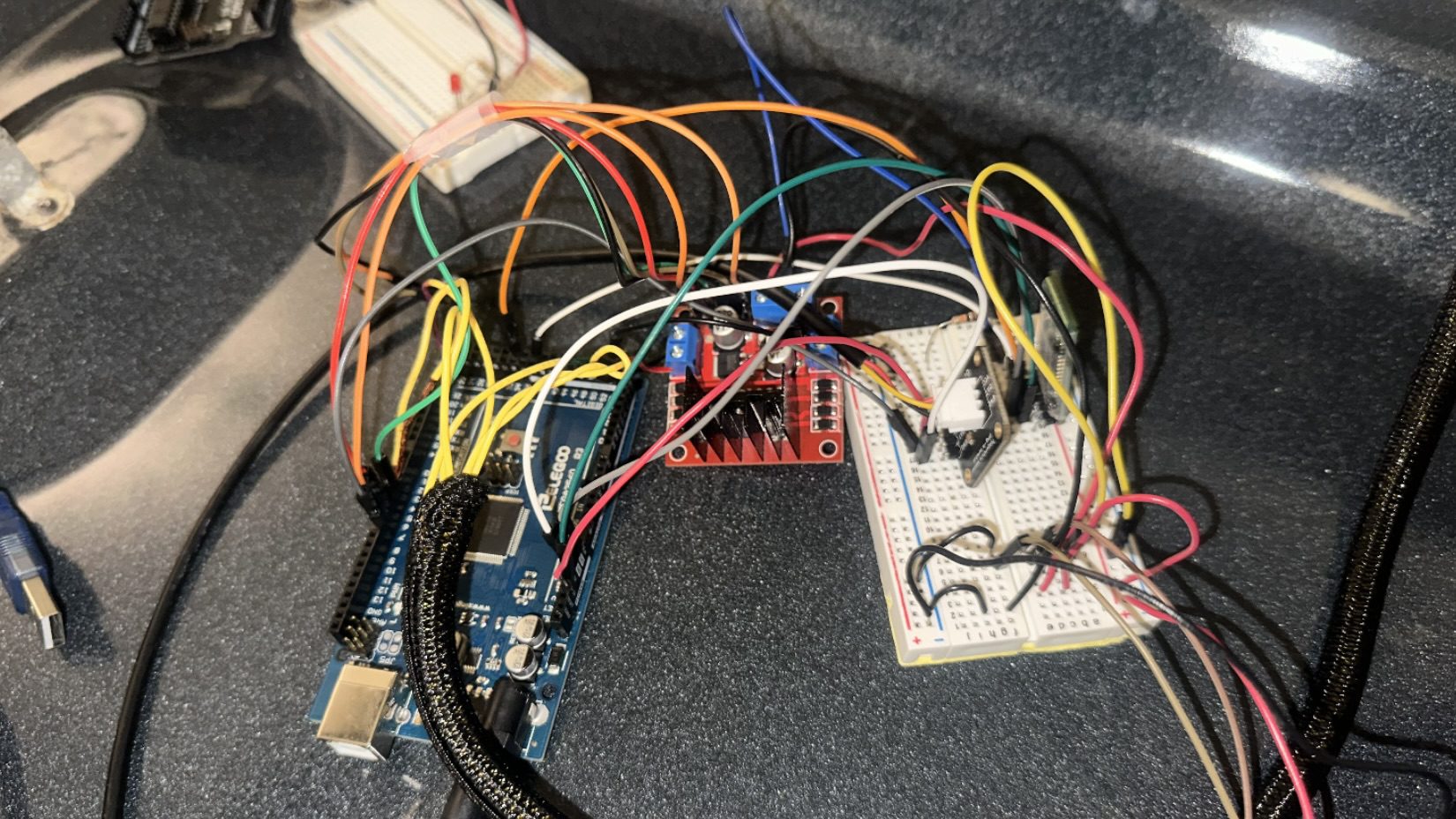

Electronics

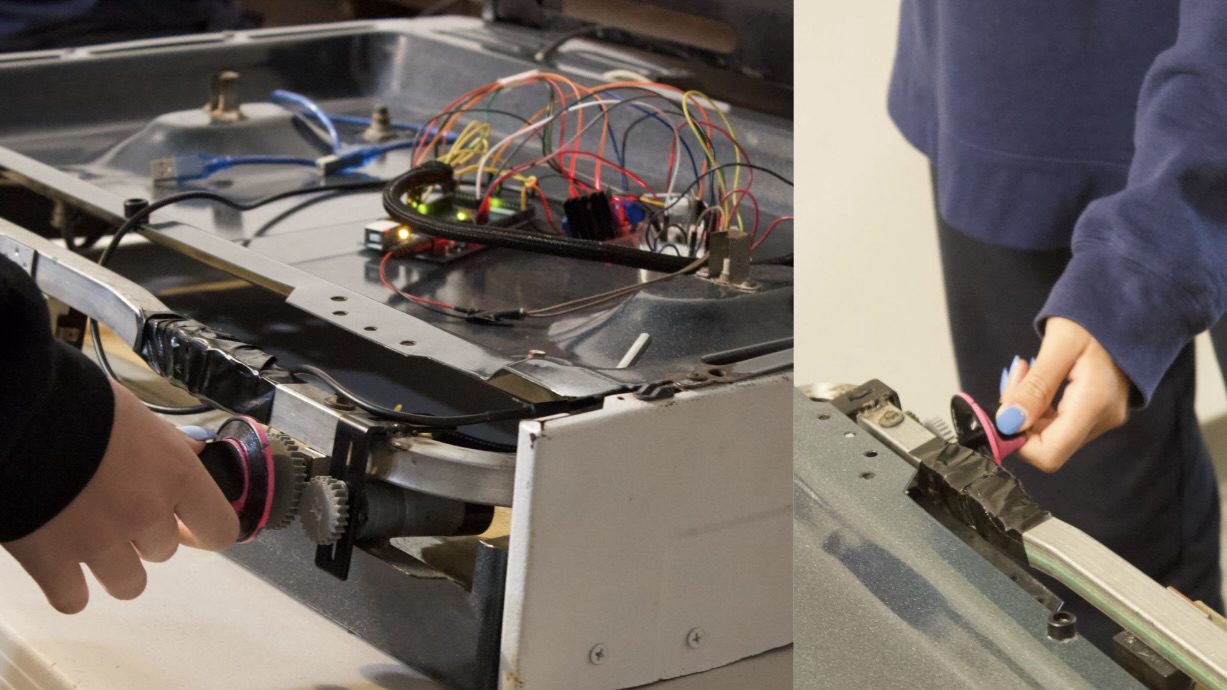

Design

Design Specifications

Less Than 800 ppm of GasThrough regular use of the product, less than 800 parts per million of gas will leak.

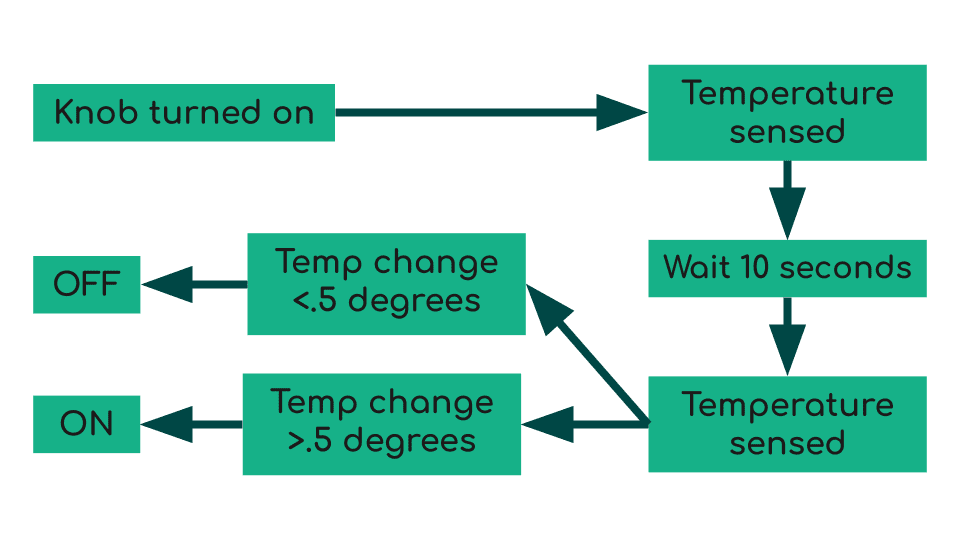

Emergency Shut OffOur product will automatically shut off when gas levels exceed safe amounts.

Young Child/Pet-ProofOur product will render the stove young child/pet-proof so it is safe to leave unattended with young kids and pets.

App That Monitors the Stove StatusThere will be an app that monitors the status of the gas flowing to the stove and allows the user to shut off the stove.

Added to Stoves From Production StageThe device will be a product that can be added to stoves from the production stage, removing any interaction from stove users.

LED IndicatorThe product will have an LED indicator that alerts the user that gas has been shut off.

Notify the User After it Has Been Shut OffThe stove will notify the user after it has been shut off and the user can easily reset it.

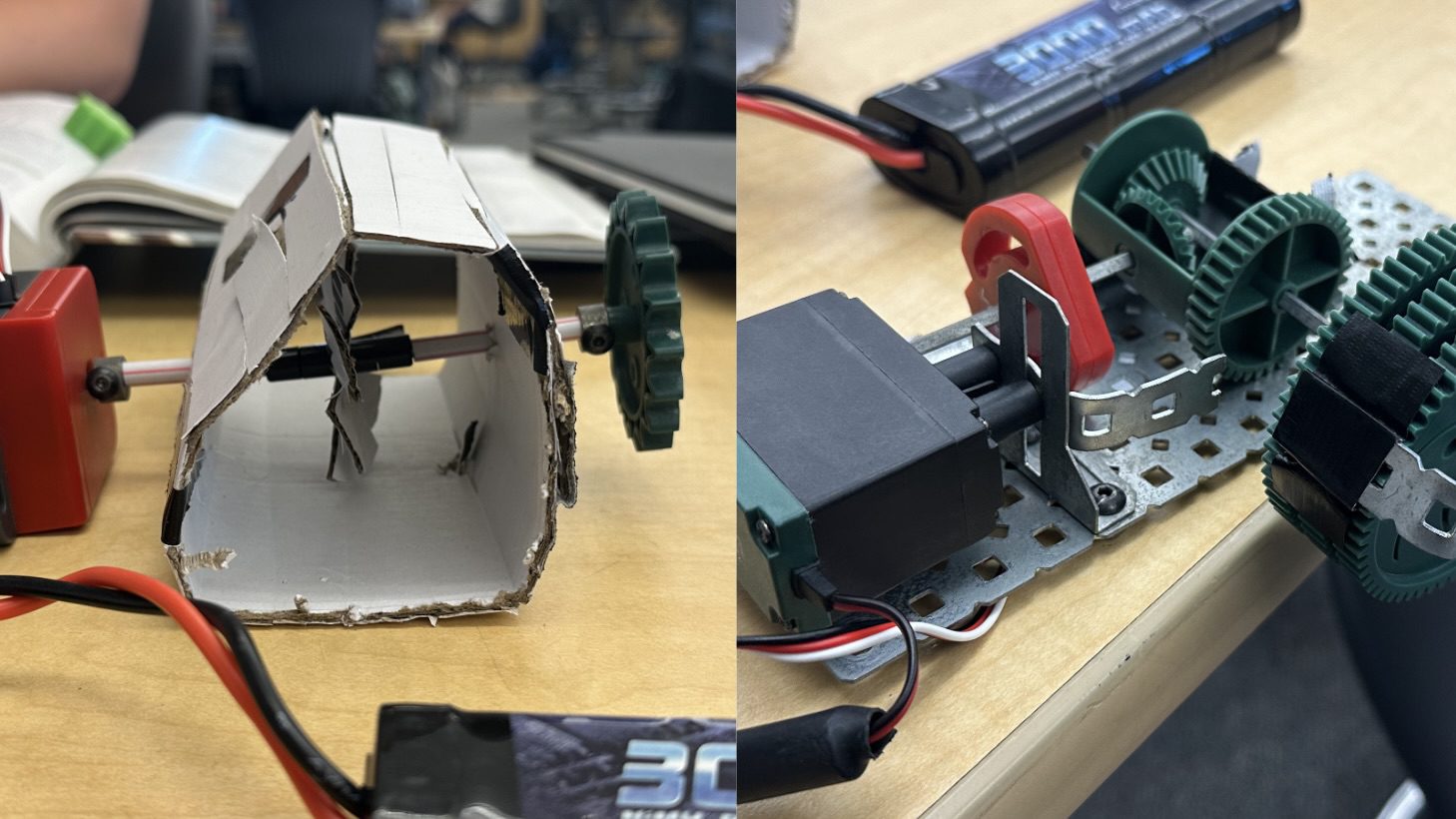

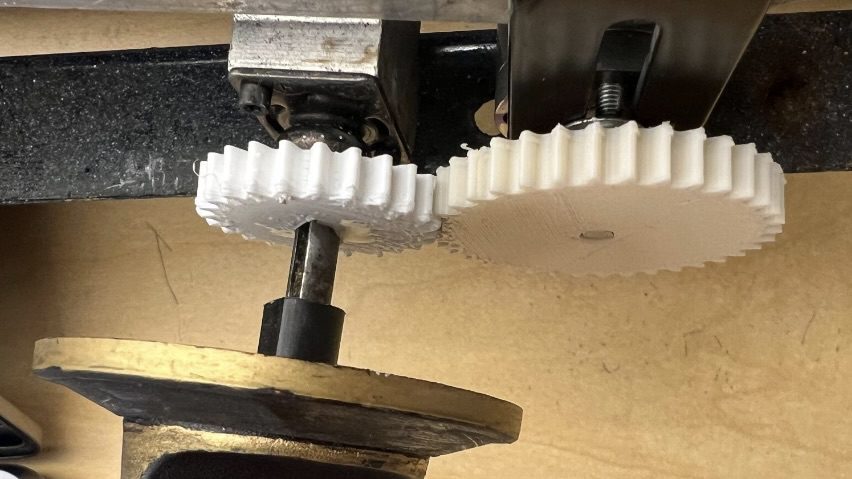

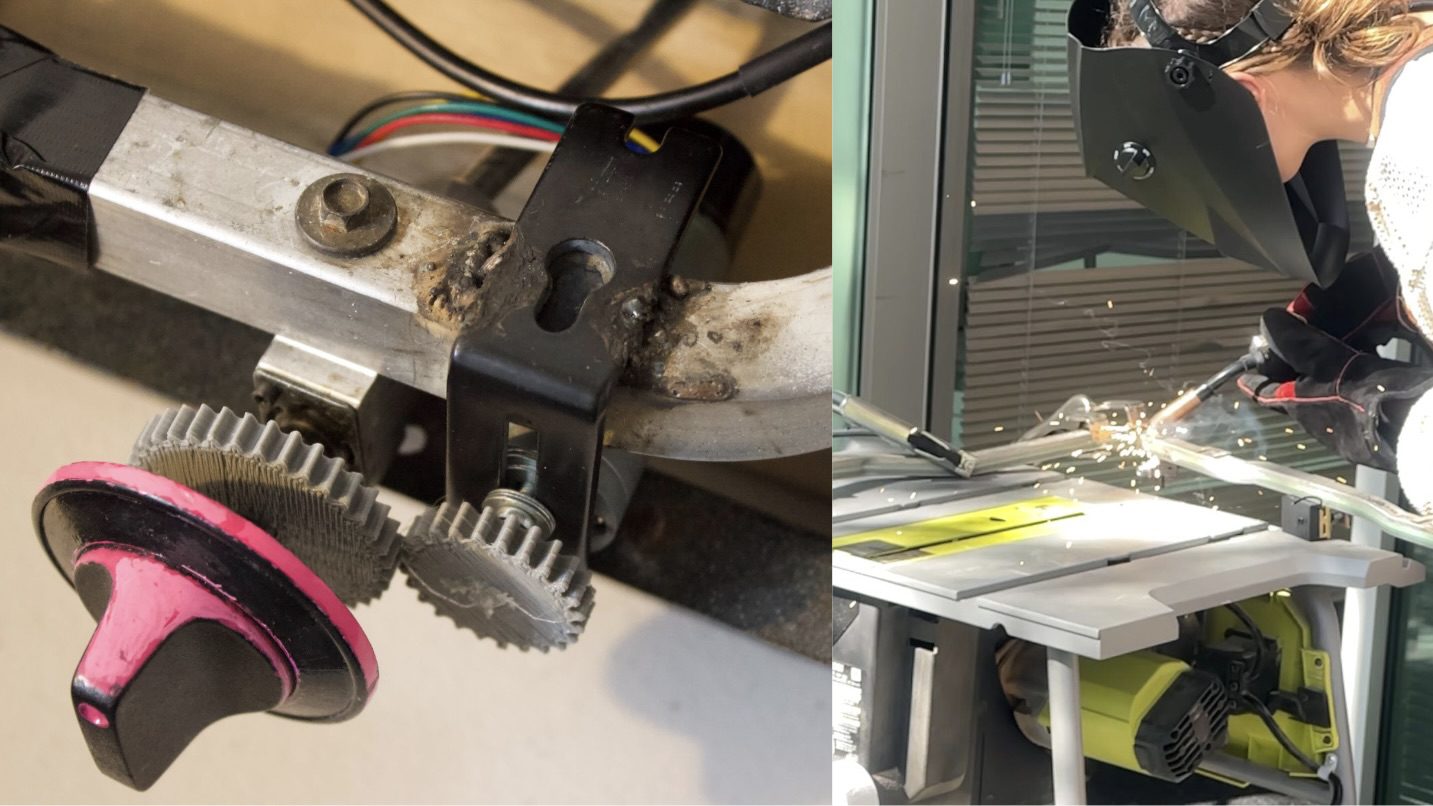

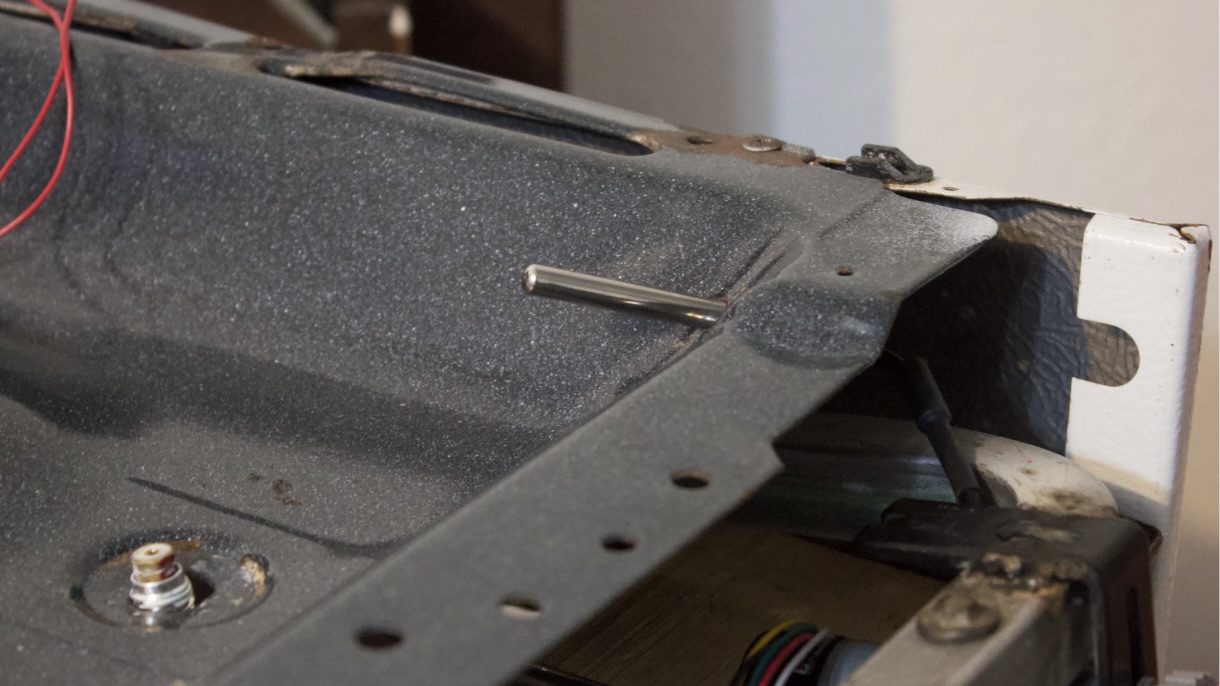

From Concept to Reality

Watch Our Presentation!

About Us

Welcome to Stove Solutions, where your safety, satisfaction, and peace of mind are our top priorities.

Our team is a powerhouse of talent and expertise:

💡 Molly Glass: Molly is one of our designers, driving our commitment to excellence and innovation. Her dedication to creating cutting-edge solutions is the important to our success.

💻 Kayla O’Neal: With years of experience in computer aided design (CAD), Kayla digitally designs elements of products before we install and test them.

💡 Lilly Sweaney: Lilly brings a creative touch to our products, making sure they are both functional and aesthetically pleasing. She believes in enhancing your cooking space while keeping it secure.

💻 Liam Walker: Liam is our coding specialist, responsible for developing our state-of-the-art monitoring systems.